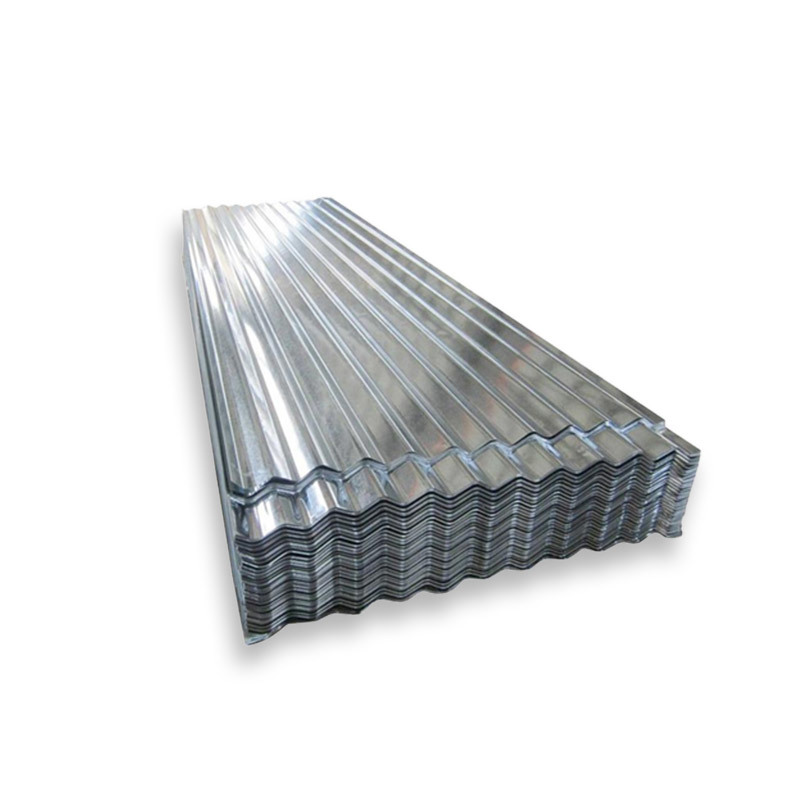

Galvanized Corrugated Roof Sheet

- Commodity name: Galvanized Corrugated Roof Sheet

Keyword:

Galvanized Corrugated Roof Sheet

- PRODUCT DESCRIPTION

-

Galvanized Corrugated Roof Sheet Description

Galvanized roof shingles are made of galvanized steel sheet used for roofing and coated with zinc. The zinc coating provides moisture and oxygen protection for the base steel. According to the galvanizing process, it can be divided into hot-dip galvanized steel plate and electro-galvanized steel plate. The corrugated design will improve its strength and enable it to withstand harsh weather conditions. Common designs include wavy, trapezoidal designs, ribbed galvanized roof panels, etc. It can be used as a single-layer board, covering an existing roof, or a steel sandwich panel.

Galvanized sheet itself is more cost-effective than traditional roofing materials. In addition, it is light in weight and easy and quick to install. In addition, it is durable and recyclable and requires less maintenance. All these factors make galvanized roof panels an economical choice. Galvanized steel roof panels have a bright and smooth surface. The corrugated design is also excellent from the outside. In addition, it has good adhesion, so you can paint it in different colors. Having a galvanized steel roof makes it easy to achieve aesthetic purposes.

Scope of ApplicationGalvanized corrugated roof panels have good corrosion resistance and long service life. Therefore, it is widely used in industry, commerce, residence and agriculture. Its wide application includes temporary houses, garages, greenhouses, warehouses, barns, stables, sheds, factories, commercial buildings, etc.

Product Parameters

Product Name Galvanized Corrugated Roof Sheet Thickness 0.12mm-6.00mm Width 600mm-1500mm Length 1m-12m, Support Customization Standard AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. Zinc Layer Hot Galvanizing: 60-275g/m² Pre-galvanized: 80-275g/m² Chemical Composition

Standard

Grade

C

Si

Mn

P

S

Ti

Forcold Forming

Chinese Standard

DX51D+Z

0.12

0.50

0.60

0.100

0.045

0.30

DX52D+Z

0.12

0.50

0.60

0.100

0.045

0.30

DX53D+Z

0.12

0.50

0.60

0.100

0.045

0.30

DX54D+Z

0.12

0.50

0.60

0.100

0.045

0.30

DX56D+Z

0.12

0.50

0.60

0.100

0.045

0.30

DX57D+Z

0.12

0.50

0.60

0.100

0.045

0.30

Forcold Forming

Japanese Standard

SGCC

0.15

0.50

0.80

0.050

0.030

0.025

SGCD1

SGCD20.12

0.100.50

0.500.60

0.450.040

0.0300.030

0.0300.025

0.025SGCD3

0.08

0.50

0.45

0.030

0.030

0.025

SGCD4

0.06

0.50

0.45

0.030

0.030

0.025

For Structure

Japanese Standard

SGC340

0.25

0.50

1.70

0.200

0.035

0.025

SGC400

SGC4400.25

0.250.50

0.501.70

2.000.200

0.2000.035

0.0350.150

0.150SGC490

0.30

0.50

2.00

0.200

0.035

0.025

SGC510

0.30

0.50

2.50

0.200

0.035

0.025

For Structure

AISI Standard

S220GD+Z

0.20

0.60

0.70

0.100

0.045

0.025

S250GD+Z

0.20

0.60

0.70

0.100

0.045

0.025

S280GD+Z

0.20

0.60

0.70

0.100

0.045

0.025

S320GD+Z

0.20

0.60

0.70

0.100

0.045

0.025

S350GD+Z

0.20

0.60

0.70

0.100

0.045

0.150

S550GD+Z

0.20

0.60

0.70

0.100

0.045

0.150

Mechanical Properties

Grade

Yield Strength MPa≥

Tensile Strength MPa≥

Elongation A%≥

DX51D Z/ZM/AZ/AM

240-380

270-500

22

DX52D Z/ZM/AZ/AM

140-300

270-420

26

DX53D Z/ZM/AZ/AM

140-260

270-380

30

DX54D Z/ZM/AZ/AM

120-220

260-350

36

S220GD Z/ZM/AM

220

300

20

S250GD Z/ZM/AZ/AM

250

330

19

S280GD Z/ZM/AM

280

360

18

S300GD A/AM

300

380

18

S320GD Z/ZM/AM

320

390

17

S350GD Z/ZM/AZ/AM

350

420

16

S450GD A/AM

450

480

15

S550GD Z/ZM/AZ/AM

550

550

-

Galvanized Surface Selection

Zero Spangle

Minimized Spangle

Normal Spangle

Large Spangle

Use of The Environment

Recommended Zinc Thickness

Indoor Use

Z10 or Z12 (100g/㎡or 120g/㎡)

Suburbs

Z20 and Painting (200g/㎡)

Urban or Industrial Area

Z27 (270g/㎡) or G90 (US Standard) and painted

Coastal Area

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted

Punch or Deep Drawing Application

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping

Surface Treatment Type

Code

Features

Chromic Acid Treatment

C

Good corrosion resistance, suitable for bare state

Chromic Acid Treatment+Oiling

S

Good corrosion resistance

Phosphoric Acid Treatment (Including Sealing Treatment)

P

Have a certain corrosion resistance, good paint performance

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling

Q

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage

Phosphoric Acid Treatment (Excluding Sealing Treatment)

T

Have a certain corrosion resistance, good paint performance

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling

V

Has a certain corrosion resistance, good paint performance, and prevent rust

Oiling

O

Prevent rust during transportation and storage

No Treatment

M

Suitable for immediate painting

Material Comparison

Chinese Standard

Japan Standard

European Standard

DX51D Z/DC51D Z (CR)

SGCC

DX51D Z

DX52D Z/DC52D Z

SGCD1

DX52D With

DX53D Z/DC53D Z/DX54D Z/DC54D Z

SGCD2/SGCD3

DX53D Z/DX54D Z

S220/250/280/320/350/550GD Z

SGC340/400/440/490/570

S220/250/280/320/350GD Z

DX51D Z/DD51D Z (HR)

SGHC

DX51D Z

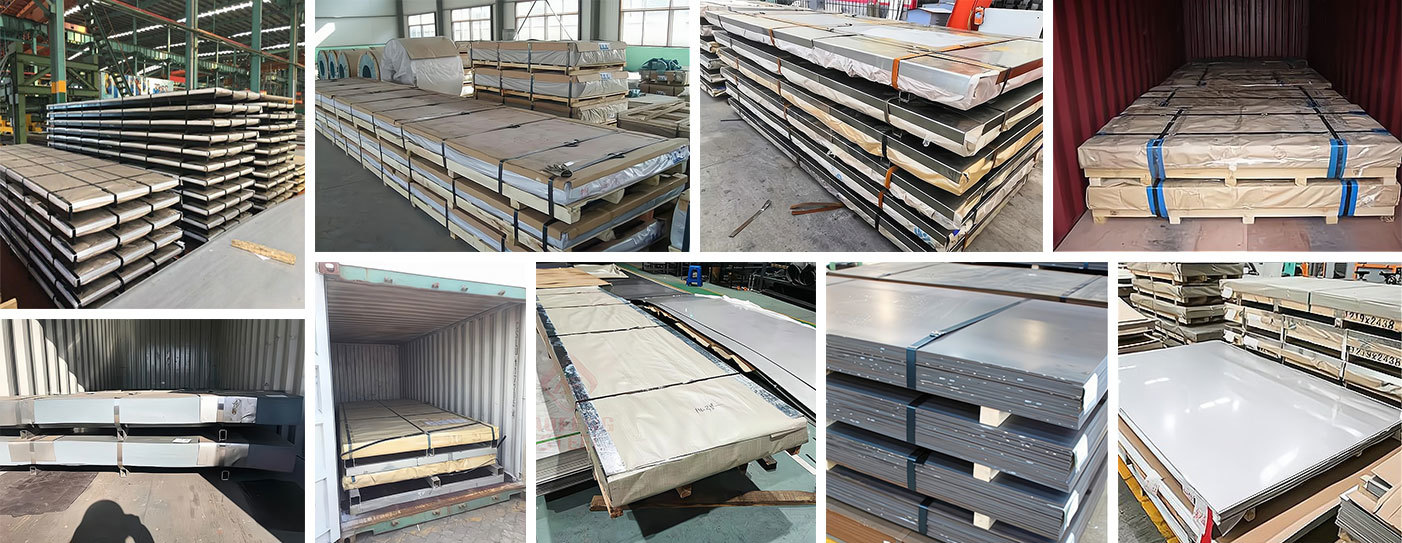

Packing and delivery

Its main products include cold-rolled annealed plates, cold-rolled coated plates, hot-rolled steel, medium and thick plates, large profiles, medium profiles, bars, wires and other products. Among them, aluminum-coated steel, zinc-aluminum-magnesium coated steel, structural steel, mining steel, ultra-high strength steel and other products are well-known throughout the country.

Packing And Delivery

FACTORY APPEARANCE

CUSTOMER PHOTO

Get A Quote

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products